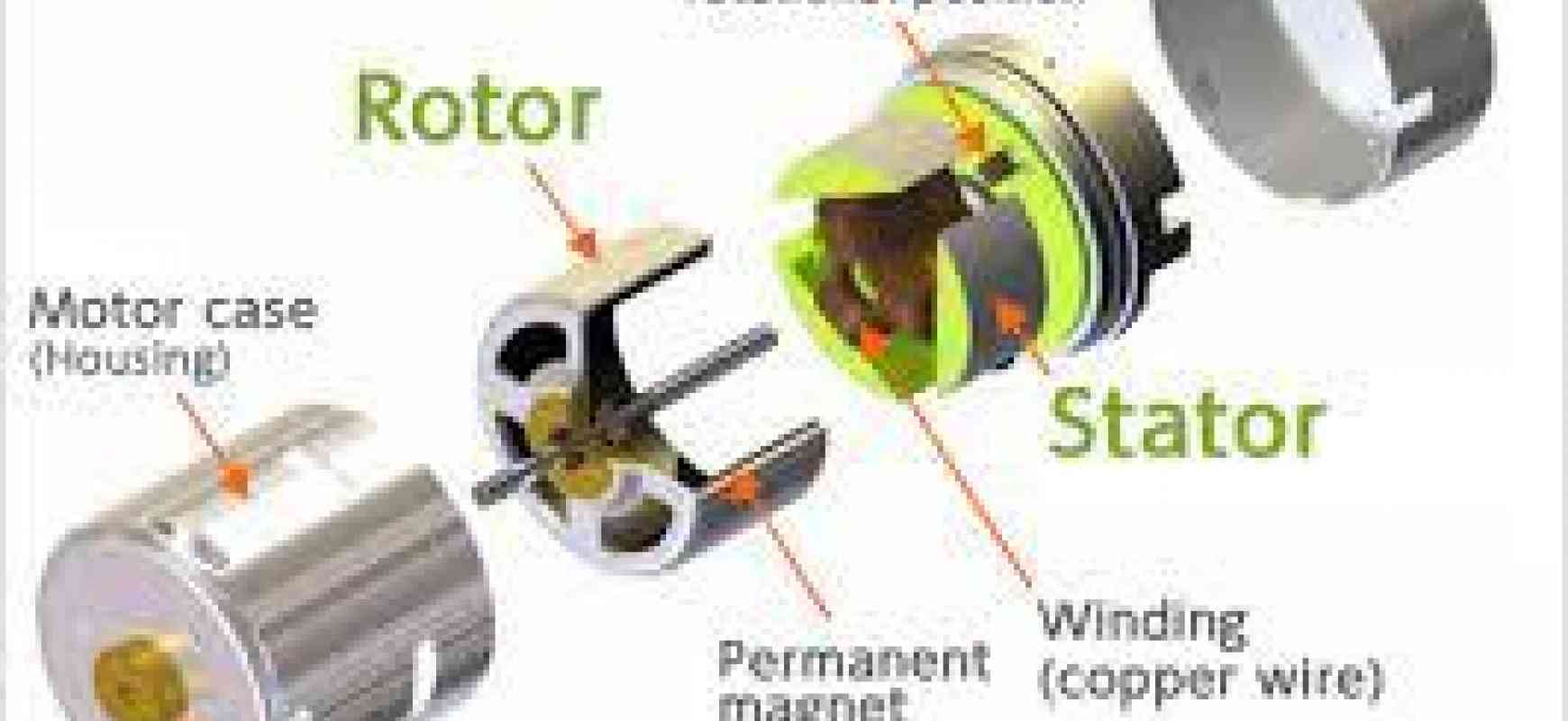

IMI is uniquely positioned to offer solutions to the challenges of motor design with extruded neodymium magnets for brushless DC motors. One of the challenges in motor design is obtaining magnet

magnets for brushless DC motors. One of the challenges in motor design is obtaining magnet prototypes to prove out your design. Once the design reaches prototype stage, the next challenge is tooling all the components, including the magnet

prototypes to prove out your design. Once the design reaches prototype stage, the next challenge is tooling all the components, including the magnet which IMI offers in many different sizes. Replacing individual arc segments or slabs with a multi pole ring magnet

which IMI offers in many different sizes. Replacing individual arc segments or slabs with a multi pole ring magnet is also an obstacle that IMI is happy to help with.

is also an obstacle that IMI is happy to help with.

Review our E-Commerce website at: MAGNETS ONLINE.COM or call us at (219) 465-1998 and request more information. Choosing bonded neodymium magnets can also be a great choice, but it still requires lead time and tooling.

magnets can also be a great choice, but it still requires lead time and tooling.

Extruded neodymium magnets are made by extruding bonded neodymium

magnets are made by extruding bonded neodymium compound through a die with established outer and inner diameters. International Magnaproducts, Inc. offers an easy solution to rapid prototyping and higher yields on motor assembly with consistent magnetic performance. Also, with isotropic material characteristics, the final magnet

compound through a die with established outer and inner diameters. International Magnaproducts, Inc. offers an easy solution to rapid prototyping and higher yields on motor assembly with consistent magnetic performance. Also, with isotropic material characteristics, the final magnet can be magnetized to any multi pole pattern, including skew patterns, either before or after shell assembly.

can be magnetized to any multi pole pattern, including skew patterns, either before or after shell assembly.

Finally, because these magnets are extruded, they can be length adjusted to support a variety of motors within a motor frame family. IMI offers virtual face-to-face design capabilities in real-time through our MagnaVision video conferencing system. We can review and offer solutions for your specific drawings, applications, machines, or magnetic needs any time you seek our help with magnetic decisions.

If you would like to try this material, with energy products of 10-13 MgOe, please contact IMI at (219) 465-1998 or email us at sales@magnetsim.com for a quotation and samples. -Brian Coleman, Solutions Engineer

IMI – specialists in the magnetic world.